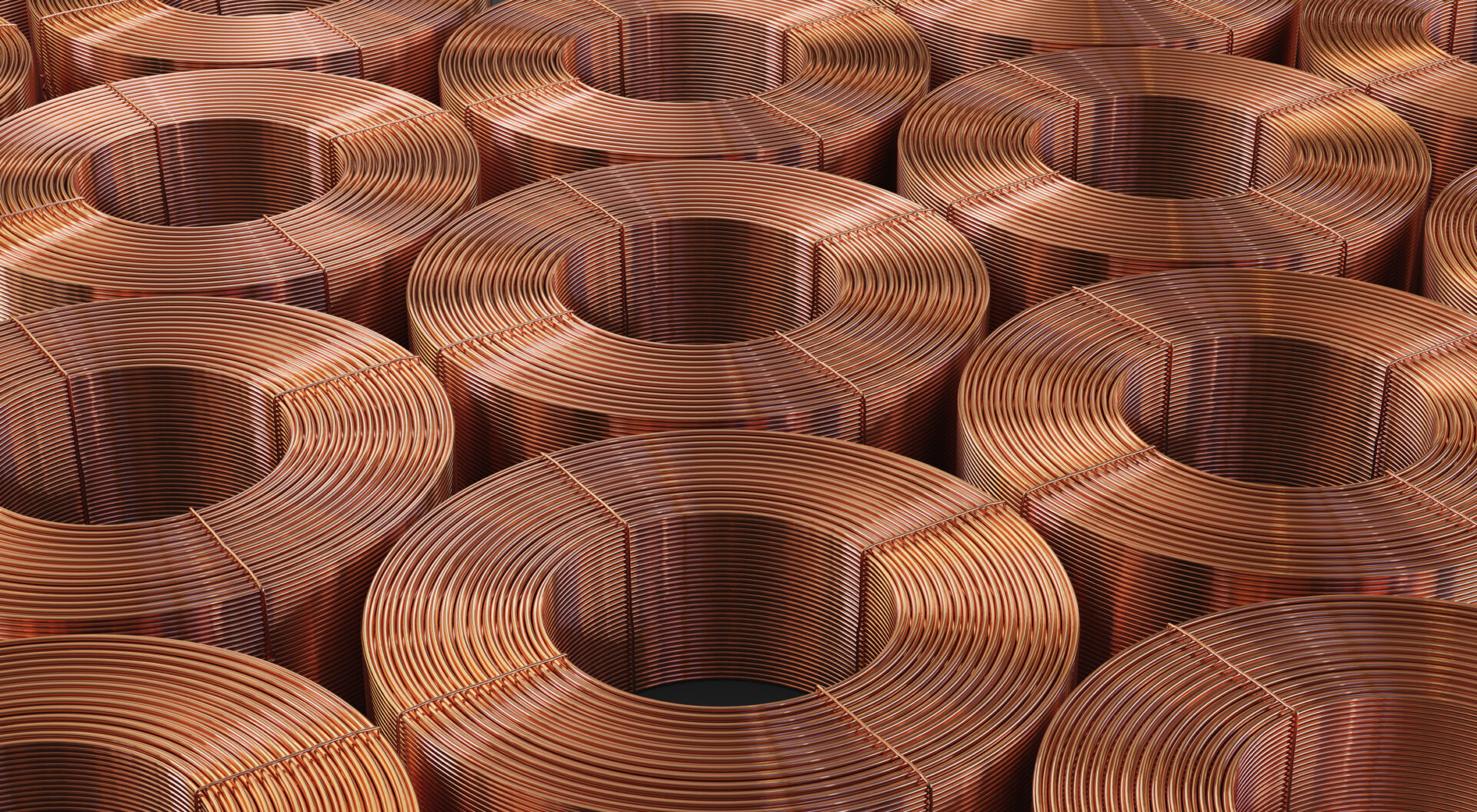

Copper

Have trouble finding a reliable company that provides quality copper for your construction needs? Warner Brothers Foundry Company is a full-service aluminum, brass and bronze casting foundry servicing various industries. We offer non-ferrous castings using air-set sand to make common alloy castings for a wide array of applications, including copper piping, prototype drum pedals, tubes and automotive parts.

Our Copper Alloys

Copper alloys usually differ from pure copper, comprising intricate compositions of copper as a base metal along with alloying elements like nickel, aluminum, silicon, tin and zinc. These elements vary in concentration to give specific properties to the alloy.

Common applications of copper alloys include:

- Electrical connectors: Copper alloys are ideal for electrical connectors in various electronic devices due to their excellent conductivity.

- Medical equipment: These alloys can also be used in surgical instruments and implantable devices.

- Components for the oil and gas industry: Copper alloys are often used in the oil and gas industry to manufacture components requiring high strength and corrosion resistance.

Copper Alloy C110

Also known as electrolytic tough pitch (ETP) copper, C110 is a pure copper alloy with a minimum copper content of 99.99%. The other 0.1% is oxygen. The “C” stands for copper, and “110” is a number assigned by the American Society for Testing and Materials (ASTM) to indicate the composition and properties of the alloy. C110 copper is highly ductile, malleable and conductive, making it suitable for various applications such as electrical wiring, where electricity flows from one point to another.

This tough-pitch copper alloy is corrosion-resistant, making it ideal for indoor and outdoor components. It also has excellent thermal conductivity and is typically free from hydrogen embrittlement due to its high purity and lack of hydrogen-containing impurities.

Copper Alloy C81100

C81100 is a copper alloy consisting of 99.7% pure copper with specific additions of silver and other elements, often called silver-bearing copper. This alloy offers increased strength, enhanced thermal and electrical conductivity and improved corrosion resistance. These properties make C81100 copper ideal for various applications, including bus conductor components, blast furnace tuyeres and oxygen nozzles.

Learn More About Our Copper Castings

Our family-owned and operated business offers quality, speed and craftsmanship that exceed customer expectations. Trust Warner Brothers Foundry Company for all your metal casting needs, and we will help set your project up for success.

Explore our extensive casting services and request a quote to get started.