C922oo Alloy

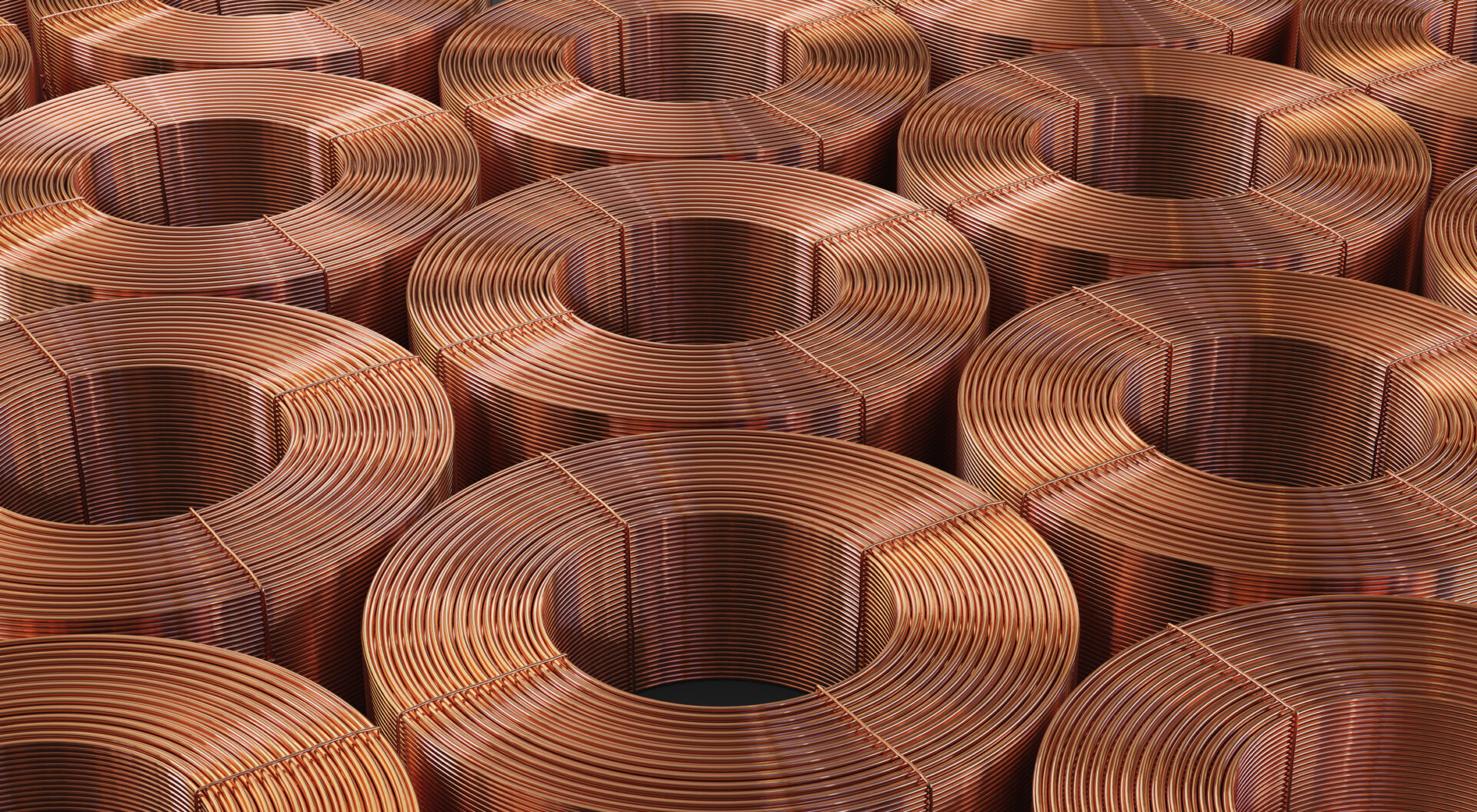

C922 alloy’s versatility makes handling casting projects easier. This high-quality leaded tin bronze alloyed copper-based casting material has several properties that make it ideal in various applications.

What Is C92200 Leaded Tin Bronze Alloy Made Of?

Several chemicals make up the tin bronze alloy known as C922 or C92200.

These chemical elements represent the composition based on its minimum and maximum values:

- Copper (Cu): Its minimum composition is 86% and its maximum is 90%. It is the main material used to produce the C922 alloy.

- Nickel (Ni): Includes carbon monoxide in its 1% maximum composition capacity.

- Lead (Pb): Comprised of a minimum composition of 1% and a maximum of 2%.

- Zinc (Zn): Includes a minimum of 3% and a maximum of 5% zinc contribution.

- Tin (Sn): Tin contributes a minimum of 5.5% and a maximum of 6.5%.

- Iron (Fe): Constitutes a maximum of 0.25% in C922 alloy.

Other elements with less than 1% contributions include phosphorous, aluminum, sulfur, antimony and silicon.

Properties of C922 Navy M Tin Bronze Alloy

Leaded tin bronze alloy has various properties suitable for high tensile strength casting applications. Some of its main physical properties include:

- Melting points: Reaches liquidus at 1810 degrees Fahrenheit and solidus at 1518 degrees Fahrenheit

- Density: A 0.312 pound-to-cubic-inch density at 68 degrees Fahrenheit

- Conductivity: According to IACS, electrical conductivity is 14% and thermal conductivity is 40.2, both at 68 degrees Fahrenheit

- Coefficient of thermal expansion: The coefficient is 10 between 68 degrees Fahrenheit to 572 degrees Fahrenheit

- Tension elasticity: 14000 ksi

- Incipient melting: 600 degrees Fahrenheit

Navy M tin alloy’s casting characteristics vary. The specific attributes are distinguished by their level:

- Yield: Medium

- Drossing: Low

- Fluidity: Medium

- Gassing: Medium

- Section size effect: High

This alloy type’s fabrication properties make it most suitable for soldering and brazing, and it has a machinability rating of 42. However, it is unsuitable for oxyacetylene welding, gas-shielded arc welding and coated metal arc welding.

| Alloy Information | … | Suitability for being joined by: | … | … | … | Typical Mechanical Properties | ||||||||||||||||||||||||||||||||

| CA# | Ingot # | Previous Trade Name | Alloy Name | Nominal Composition | ASTM | Federal | Former Federal | Military | Approx. Weight, lb./in.3 | Soldering | Brazing | Castability (Ranked 1-8, 1 is the best or highest) | Fluidity (Ranked 1-8, 1 is the best or highest) | Machinability Rating (Free Cutting Brass = 100) | Tensile Strength, ksi | Yield Strength, ksi | Elongation, Percentage in 2 in. | Shear Strength, ksi | Fatigue Strength (100 million cycles), ksi | Brinell Hardness (500-kg Load) *(3000-kg Load) | Shrinkage Allowance | Pattern Maker's Shrinkage | ||||||||||||||||

| 922 | 245 | Navy M | Tin Bronze | 86-6-1.5-4.5 | B584, B61, B271, B505, B30 | QQ-C-390, QQ-C-525 | QQ-B-1005, QQ-C-390, QQ-L-225 | MIL-B-16541, MIL-B-15345 | 0.312 | Excellent | Excellent | 3 | 6 | 42 | 40 | 20 | 30 | … | 11 | 65 | 1.50% | 3/16 in./ft | ||||||||||||||||

C922 Bronze Alloy Common Applications

C922 alloy is commonly used in the industrial sector to produce valves, nuts, oil pumps, pump impellers, gears, bushings, hydraulic equipment, piston rings and bearings. Additionally, it is used in these industries and applications:

- Architecture: Ornamental castings for its high corrosion resistance and excellent machining properties.

- Marine: Marine castings for superior fresh water and saline solution resistance, fair machinability and modest strength.

- Building: Cooling and heating equipment for its outstanding corrosion resistance, high thermal conductivity and exceptional machining properties.

- Plumbing: It sustains pressure steam equipment up to 550 degrees Fahrenheit, with high corrosion resistance, pressure tightness, strength retention at high temperatures and good machinability.

Casting specifications relate to its different forms as follows:

- Centrifugal cast: Copper base alloy centrifugal, wrought and cast copper alloys

- Continuous cast: Copper base alloy continuous castings, wrought and cast copper alloys

- Sand cast: Copper alloy sand castings, steam, valve bronze and wrought and cast copper alloys

- Fitting: Brass and bronze pipe fittings, steam or valve bronze castings and bronze pipe flanges

- Flanges: Brass and bronze pipe fittings and steam or valve bronze castings

- Ingot: Copper base alloys

| CA# | Ingot # | Previous Trade Name | Alloy Name | Nominal Composition | Applications |

| 922 | 245 | Navy M | Tin Bronze | 86-6-1.5-4.5 | Component castings of valves, flanges and fittings, oil pumps, gears, bushings, bearings |

Contact Us for C92200 Alloy Castings Today

Perfect your next casting project with C922 alloy, which is preferred for its corrosion resistance, strength, machinability and other exceptional properties. Contact us to request a quote today.